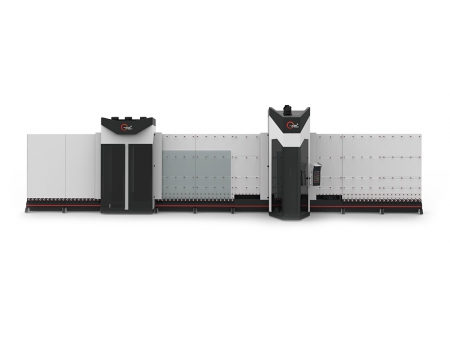

DW4-63 High Speed Thermoforming Machine (Forming, Punching, Cutting, Stacking)

Descripción

DW4-63 high speed thermoforming machine with forming area of 630*440mm has four stations, which are respectively responsible for forming, punching, cutting and stacking. The machine is suitable for variety of materials such as PP, PS, OPS, PET, PVC, PE, PLA and so on. What’s more, the machine is especially suitable for manufacturing plastic packaging products with holes such as fruit containers, plastic cover and so on. Besides, the machine can also be used to manufacture all kinds of plastic containers and bowls, which is widely applied to various packaging fields such as food packaging, electronics packaging and medical supplies packaging and so on.

Proceso técnico

| Área maxima de formación | mm | 630×440 |

| Área minima de formación | mm | 310×250 |

| Tamaño máximo de herramienta | mm | 630×440 |

| Grosor adecuado de la lámina | mm | 0.1-2.5 |

| Profundidad de formación | mm | ≤±120 |

| Eficiencia de trabajo | pcs/min | ≤50 |

| Consumo máximo de aire | L/min | 4500-5000 |

| Potencia de calentamiento | kW | 76.8 |

| Dimensiones de la máquina | m | 12.4L×2.1W×2.5H |

| Peso total | T | 14 |

| Potencia nominal | kW | 112 |

Feature of DW series high speed thermoforming machine

1. DW4-63 high speed thermoforming machine has high manufacturing speed and the maximum speed can be up to 50 cycles per minute.

2. Our machines are all equipped with absolute value servo control system and operation interface of number axis aided parameter display and advanced automatic system, which can keep superior performance of processing PP, PS, OPS, PE, PVC, APET, CPET, etc.

3. We also adapt simple mould replacing system according to ergonomic principle, which can largely reduce the time for replacing mould.

4. The cutting type of steel blade can be cooperated with the design of stacking equipment, which is beneficial to improve manufacturing speed and ensure the maximum production area.

5. The series of machine is equipped with advanced heating system with new temperature control module and short response time, which can reduce energy consumption and improve working efficiency.

6. The series of DW type thermoforming machine has low noise at working and has high reliability, which is very convenient for maintenance and operation.