Resin Coating Dust Proof LED Light Strip IP64

Resin Coating Dust Proof LED Light Strip IP64

Technological advantages

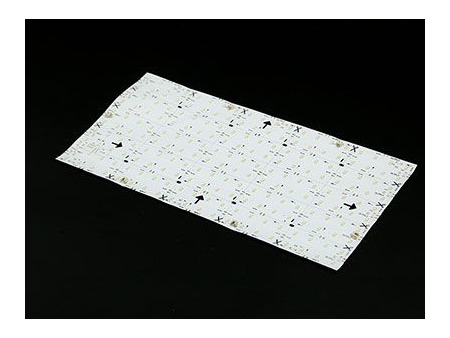

1. The base of the resin coating dust proof LED light strip is flat and flexible, enabling the strip light to be created into variety of forms.

2. This LED strip’s small size and low voltage makes this lighting ideal for a wide range of applications.

3. Typically, the dustproof LED light strip is twice as bright as LED rope lights.

4. Can be cut to size by at marked intervals (by electricians) and rejoined by soldering or using our quick connectors at marked soldering points.

5. Rayconn resin coating dust proof LED light strip comes with a self-adhesive

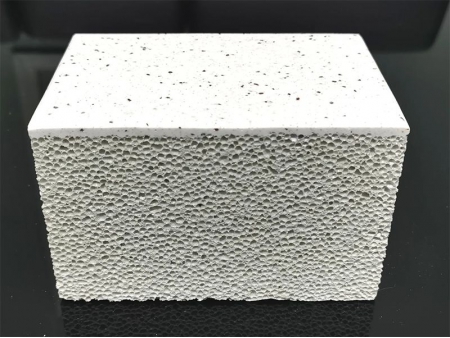

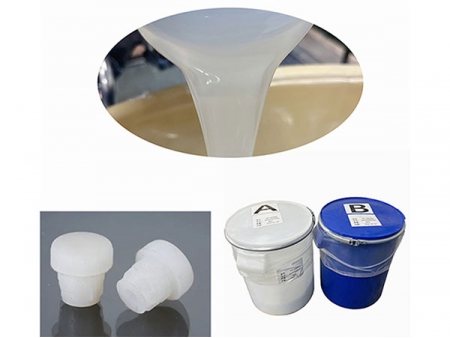

6. Resin is dipped on the surface of LED strip to keep the LEDs from dust and moisture.

7. Always install according to local electrical codes requirements.

Why choose it?

1. Available in 12 or 24 volts.

2. Super Bright SMD LEDS with good color consistency is adopted as the light source of the LED ribbon light.

3. Customized CCT LED is available.

4. Little or no heat, low power consumption.

5. The same as other Rayconn LED lights, the LED strip light comes with a long lifespan of 30,000 hours or more.

6. The length of the resin coated dustproof LED light strip is adjustable.

7. Solid-state, high vibration resistant SMD chips.

8. Dimmable

9. Dust proof

10. All Rayconn flex LED light strips are provided with a three-year warranty time.

11. CE, Rohs recognized.

Applications

Rayconn dustproof LED light strip can be used as a type of decorative lighting fixture for cove lighting and back lighting at homes and in hotels, stores, yachts, bars, automobiles, etc. It can also be applied for general illumination in any places for the purpose of saving energy consumption. Moreover, LED strips can also be used for guidance lighting for cinemas, theatres, yachts, trains to guide people move around safely as well as channel letter lighting for your stores, restaurants, bars, etc.

International markets

Germany, UK, Spain, France, Italy, Austria, Switzerland, Belgium, The Netherlands, Greece, Sweden, Norway, Denmark, Portugal, United States, Canada, Australia, Brazil, South Africa, etc.

Safety and maintenance information

1. The installation of Rayconn flexible LED light strip should be conducted by qualified technicians, and specific electrical and safety standards need to be followed.

2. All applicable electrical and safety standards should be considered while installing the LED strip or related parts like power supply, LED controller, etc.

3. While installing, attention should be paid to standard ESD precautions. It is advised to use a wrist strap during soldering to remove any static electricity. Static electricity may damage the LEDs and other flex LED light strip components.

4. The conducting paths on the flexible PC board should not be damaged during assembly. The LED strip light and all light components should not be mechanically stressed. The strip may be curved around small radii provided there are no LED components on the bend and the force does not crease the light strip. The strip should be secured down immediately to avoid fatigue and breakage.

5. The flexible LED ribbon should be connected to proper power supply.

6. During installation, please make sure the polarity id correct. Electrical polarity is printed on the LED strip and wrong polarity connection may cause damages to the LED light.

7. The LED strip can be cut to different lengths to meet different installation demands. While cutting, please cut according to the cutting marks printed on the strip light.

8. Soldering connection should only be performed on designated solder pads on the flexible LED light strip. During soldering, do not exceed the maximum soldering temperature of 260 Celsius degrees and the maximum soldering time of 10 seconds.

9. When mounting on metallic or other conductive surfaces, there should be an electrical isolation point between the strip and the mounting surface.

10. Flex LED light strip should be installed in proper environment. It’s the user’s responsibility to provide the LED ribbon with suitable protection against corrosive agents, such as moisture and condensation and other harmful elements.

Somos un aliado confiable en la fabricación de soluciones hidráulicas de alto rendimiento

hydraulicsystem-ar.com

Somos un aliado confiable en la fabricación de soluciones hidráulicas de alto rendimiento

hydraulicsystem-ar.com