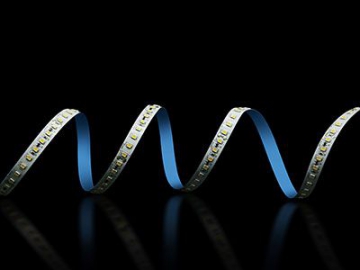

Nonwaterproof LED Strip Light

Nonwaterproof LED Strip Light

Technical advantages

1. The base of the flexible LED strip light is flat and flexible, so the LED strip can be created into variety of shapes.

2. Featuring small size and low voltage operation, the LED flexible strip is ideal for a wide range of applications.

3. With the same power, the LED strip is typically twice as bright as LED rope light.

4. Rayconn nonwaterproof LED strip light can be cut off at marked intervals by electricians and rejoined by soldering or using our quick connectors at marked soldering points.

5. Comes with a self-adhesive

Note

Always install according to local electrical codes requirements.

Why choose it?

1. Rayconn nonwaterproof LED strip light is designed with control IC, supporting numerous color-change effects.

2. Plug-in controller provides remote control function.

3. Flexible PCB and 12V low voltage input ensures operational safety and broad range of application

4. The LED light strip can be cut off every 3 LEDs. Hence, the strip length is customizable.

5. This is a absolutely environmental friendly LED lighting fixture, generating no UV and IR.

6. Extremely long lifespan and lower power consumption.

Applications

The superior lighting performance and user-friendly designs make Rayconn nonwaterproof LED strip light perfect for numerous applications. To illustrate, the LED light can be used as cove lights, back lights, cabinet lights, edge light, architectural lights for use in corridor, canopy, archway, pathways and contour marking, etc.

Rayconn nonwaterproof LED strip light provides us an ideal lighting solution for hotels, restaurants, night clubs, coffee bars, wine bars, shopping malls, various shops, cinemas, beauty centers, offices, household kitchens and living rooms, etc.

Basic technical data

Light source: 5050 3-IN-1 Top SMD LEDs

Flexible PCB thickness:

Flexible PCB width:

Height of the strip:

Entire roll length:

Number of LEDs: 15 LEDs as a basic unit. Each basic unit equals to

Beam angle: 120 deg.

Certification: CE & RoHS

Color for choice: RGB

Protective rating: IP20

| Model Number | Color | W.L | LED type | LED quantity | Light output(lumen) | Voltage (V DC) | Current (Amps) | Max. power Consumption (W) | Length (m) |

| FLB-W5050RGB-15-12FL-N12 | 618 | 5050 SMD LED | 150 | 180lm | 12 | 0.9 | 36 | 5 | |

| 515 | 450lm | 0.85 | |||||||

| 465 | 120lm | 0.82 |

International markets

Currently, Rayconn flexible LED light strip has been well received by customers from

Safety and maintenance information

1. The installation of Rayconn flexible LED strip light should be conducted by qualified technicians, and specific electrical and safety standards need to be followed.

2. All applicable electrical and safety standards should be considered while installing the LED strip or related parts like power supply, LED controller, etc.

3. While installing, attention should be paid to standard ESD precautions. It is advised to use a wrist strap during soldering to remove any static electricity. Static electricity may damage the LEDs and other flex LED strip light components.

4. The conducting paths on the flexible PC board should not be damaged during assembly. The LED light strip and all light components should not be mechanically stressed. The strip may be curved around small radii provided there are no LED components on the bend and the force does not crease the light strip. The strip should be secured down immediately to avoid fatigue and breakage.

5. The flexible LED ribbon should be connected to proper power supply.

6. During installation, please make sure the polarity id correct. Electrical polarity is printed on the LED strip and wrong polarity connection may cause damages to the LED light.

7. The LED strip can be cut to different lengths to meet different installation demands. While cutting, please cut according to the cutting marks printed on the strip light.

8. Soldering connection should only be performed on designated solder pads on the flexible LED strip light. During soldering, do not exceed the maximum soldering temperature of 260 Celsius degrees and the maximum soldering time of 10 seconds.

9. When mounting on metallic or other conductive surfaces, there should be an electrical isolation point between the strip and the mounting surface.

10. Flex LED strip light should be installed in proper environment. It’s the user’s responsibility to provide the LED ribbon with suitable protection against corrosive agents, such as moisture and condensation and other harmful elements.