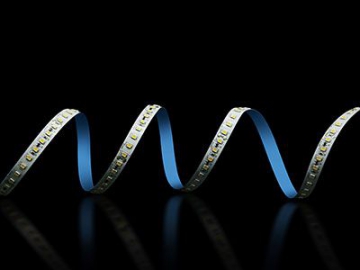

12W High Power Rigid LED Light Strip

12W High Power Rigid LED Light Strip

Technical advantages

1. This 12w high power rigid LED light strip is energy saving and characterized by low heat generation and compact size.

2. 12V safe working voltage.

3. Multi-colors optional.

4. Generating no IR and UV, this LED light is eco-friendly.

Why choose Rayconn?

1) Adopting 12 pcs high power 1W LEDs as the light source, Rayconn rigid LED light strip has high brightness.

2) Aluminum PCB ensures optimal heat dissipation.

3) Good light color consistence.

4) CE and RoHs compliant

Applications

The high brightness and long service life make this 12W high power rigid LED light strip ideal for working as under cabinet light, cove light, etc. This strip light can also work with housings and lens to create many different types of LED lighting fixture.

Technical specification

Light Source: 1W high power LED

PCB Type: Aluminum alloy rigid PCB

Dimensions: L 570 x W20 x H

Optional Colors: Red / Green / Blue / Yellow / Cool White / Warm White

Protective Rating: IP20 (Non-waterproof)

| Part No | Dimension | Light Color | Lumen | LED type / Qty | Input | Power |

| RLB1-HP1V-12-12 | L570*W20*H 2.0 mm | Red | 480 lm | 1W power LED / 12 pcs | 12V DC | 12 W |

| RLB1-HP1PG-12-12 | L570*W20*H 2.0 mm | Green | 610 lm | 1W power LED / 12 pcs | 12V DC | 12 W |

| RLB1-HP1B-12-12 | L570*W20*H 2.0 mm | Blue | 95 lm | 1W power LED / 12 pcs | 12V DC | 12 W |

| RLB1-HP1Y-12-12 | L570*W20*H 2.0 mm | Yellow | 380 lm | 1W power LED / 12 pcs | 12V DC | 12 W |

| RLB1-HP1W3-12-12 | L570*W20*H 2.0 mm | Cool White | 660 lm | 1W power LED / 12 pcs | 12V DC | 12 W |

| RLB1-HP1W6-12-12 | L570*W20*H 2.0 mm | Warm White | 610 lm | 1W power LED / 12 pcs | 12V DC | 12 W |

International markets

Due to its variety of advantages, our 12w high power rigid LED strip lights are well received by customers from Germany, UK, Spain, France, Italy, Austria, Switzerland, Belgium, The Netherlands, Greece, Sweden, Norway, Denmark, American, Canada, etc.

Safety and maintenance information

1. The installation of Rayconn rigid LED light strip should be conducted by qualified technicians, and specific electrical and safety standards need to be followed.

2. All applicable electrical and safety standards should be considered while installing the LED strip or related parts like power supply, LED controller, etc.

3. While installing, attention should be paid to standard ESD precautions. It is advised to use a wrist strap during soldering to remove any static electricity. Static electricity may damage the LEDs and other rigid LED light strip components.

4. The conducting paths on the PC board should not be damaged during assembly. The LED light strip and all light components should not be mechanically stressed.

5. This LED lighting fixture should be connected to proper power supply.

6. During installation, please make sure the polarity id correct. Electrical polarity is printed on the LED strip and wrong polarity connection may cause damages to the LED light.

7. The LED rigid strip can be cut to different lengths to meet different installation demands. While cutting, please cut according to the cutting marks printed on the strip light.

8. Soldering connection should only be performed on designated solder pads on the rigid LED light strip. During soldering, do not exceed the maximum soldering temperature of 260 Celsius degrees and the maximum soldering time of 10 seconds.

9. When mounting on metallic or other conductive surfaces, there should be an electrical isolation point between the strip and the mounting surface.

10. Rayconn rigid LED light strip should be installed in proper environment. It’s the user’s responsibility to provide the LED strip with suitable protection against corrosive agents, such as moisture and condensation and other harmful elements.